Piston & Glide Rings

Piston Rings

Series 77M (Metric Sizes)

No expensive expanding arbors or re-sizing dies are required

Characteristics

Universal Seal Piston Rings were developed specifically to be totally interchangeable with the TFE piston rings currently available, and to provide a product which can be more readily installed on the pistons and provide longer field service life. Polyurethane Piston Rings manufactured from Unithane 460D material with and outer wear layer containing a concentration of Molybdenum Disulfide (MSO2). The purpose being: to provide a low friction surface during the initial break-in period of the hydraulic cylinder. Series 77 Piston Rings can be manufactured from alternate materials to meet specific design requirements. Series No. 77 – Piston Rings provide many advantages as seals.

1. Unithane piston rings expand readily to fit over the major piston diameter and recover quickly to permit immediate installation of the piston into the cylinder bore. No expensive expanding arbors or re-sizing dies are required. This results in a reduction of assembly time and eases field replacement.

2. The Superior cut strength of Unithane 460 D material in combination with an ultimate elongation of 430% insures that fewer rings are scrapped during assembly. This also helps to avoid cylinder rework by elimination damaged rings which being installed on the piston.

3. Unithane piston rings resist field failures attributed to minor scoring or galling of the cylinder bore which will cause rapid failure of piston rings made from other less abrasion and cut materials.

4. The inherent elastic memory exhibited by Unithane piston rings insures instantaneous response to rapidly varying system pressures and eliminates the objectionable compression set or “cold flow” characteristic commonly associated with TFE materials.

Unithane piston rings will operate effectively in hydraulic cylinders with pressures up to 3000 PSI and with radial clearances as great as .008 inches. The cylinder bore should be finished not to exceed 20 RMS for maximum service life although somewhat higher limits can be accepted depending on pressure and frequency of cycling.

The standard bore diameter and the corresponding groove diameter for normal application of Unithane piston rings is as shown on page 2. These recommendations conform to ANSIB93.32-1973 and NFPA STD T3.19.18-1973 Groove Dimensions for Fluid Power Radial Compression Type Piston Rings. Oversize or undersize cylinder bore diameters from -.020 to +.025 can readily be accommodated provided that an equivalent adjustment is made in the groove diameter. In extreme oversize conditions beyond +.025 the groove diameter may need to be increased slightly more than a matching equivalent and a 90 durometer O ring may be substituted for the normal 70 durometer to help maintain sufficient circumferential contact between the piston ring and the cylinder bore.

Material

- TYPE: Unithane 460D, Liquid Cast Polyurethane

- HARDNESS: Durometer 60D

- FLUID COMPATABLILITY: See ‘Material Specifications’, Technical Bulletin US-96

PISTON GLIDE RINGS

Series 88M (Metric Sizes)

Characteristics

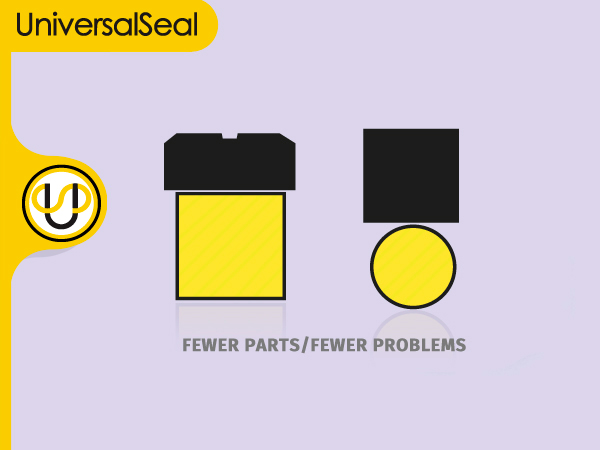

Piston Glide Rings are used in conjunction with square section nitrile rubber energizers.

The square section ensures the ring stability under varying pressures and speeds.

The Glide Ring material is a hard (65 shore D) thermoset polyurethane with a modulus to resist extrusion.

The dynamic surface is impregnated with molybdenum disulfide (MS0=E2=82=82) to reduce friction.

In addition to the standard sizes shown, which interchange with PTFE rings, tooling is available for most other metric sizes. Unlike PTFE rings, the elastic properties of the polyurethane make installation easy, without the need for special tooling.

Material

- Type: Unithane 460 D, Liquid Cast Polyurethane

- Hardness: Durometer 65 D

- Fluid Compatibility: See Material Specifications: Technical Bulletin USM-03