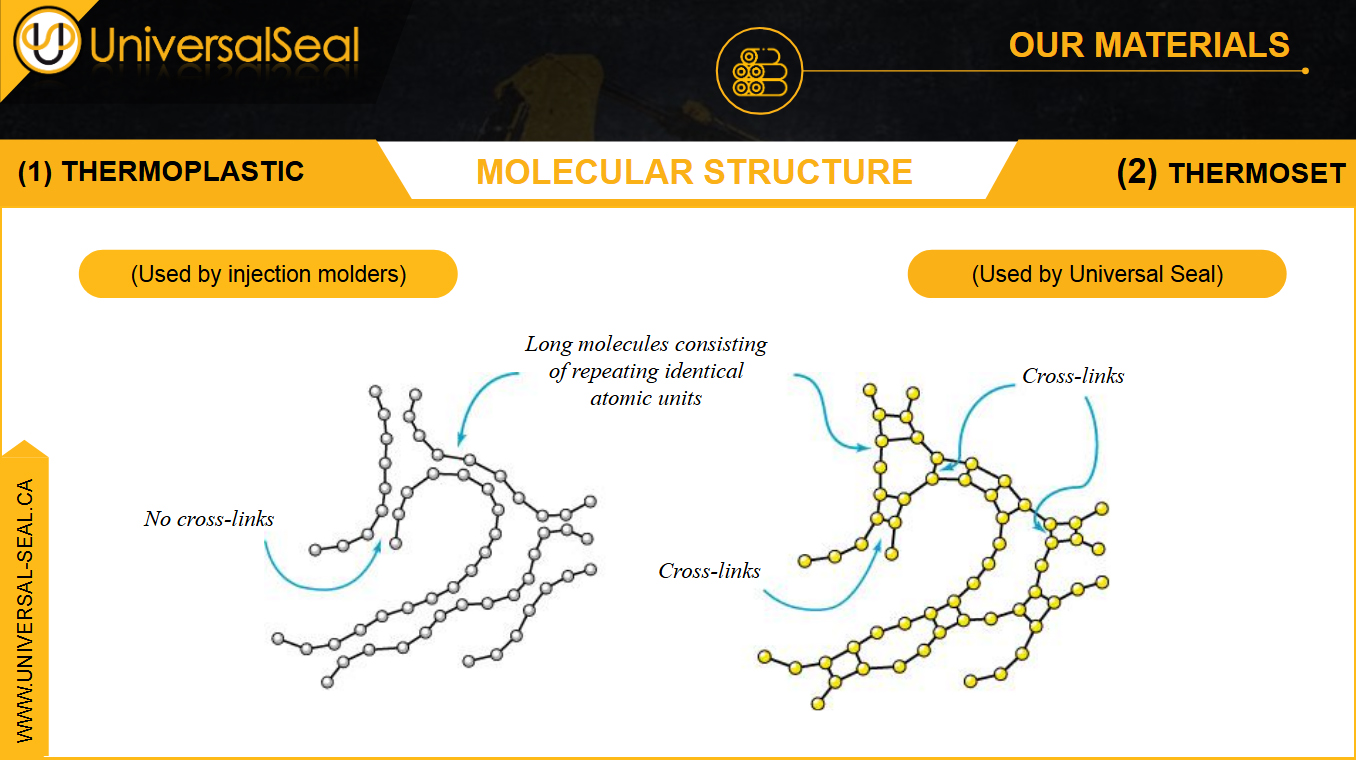

Thermoplastic vs. Thermoset: What Makes Our Material Superior at Universal Seal

At Universal Seal, we utilize thermoset polyurethane, which offers several advantages over thermoplastic polyurethane. Thermoset materials produce cross-links between long molecules, resulting in a more durable and stable structure.

Here are some key benefits of our thermoset polyurethane:

-

Higher Tensile Strength: Thermoset polyurethane generally has higher tensile strength, making it more durable and resistant to wear and tear.

-

Better Heat Resistance: Thermoset polyurethane can withstand higher temperatures without losing its shape or properties, making it ideal for applications exposed to heat.

-

Chemical Resistance: It offers superior resistance to chemicals, which is beneficial in environments where exposure to harsh substances is common.

-

Dimensional Stability: Thermoset polyurethane maintains its shape and size better over time, even under stress or high temperatures.

-

Customization: Thermoset polyurethane can be custom engineered to specific hardness levels (e.g., Shore OO, Shore A, Shore D), providing flexibility in design and application.

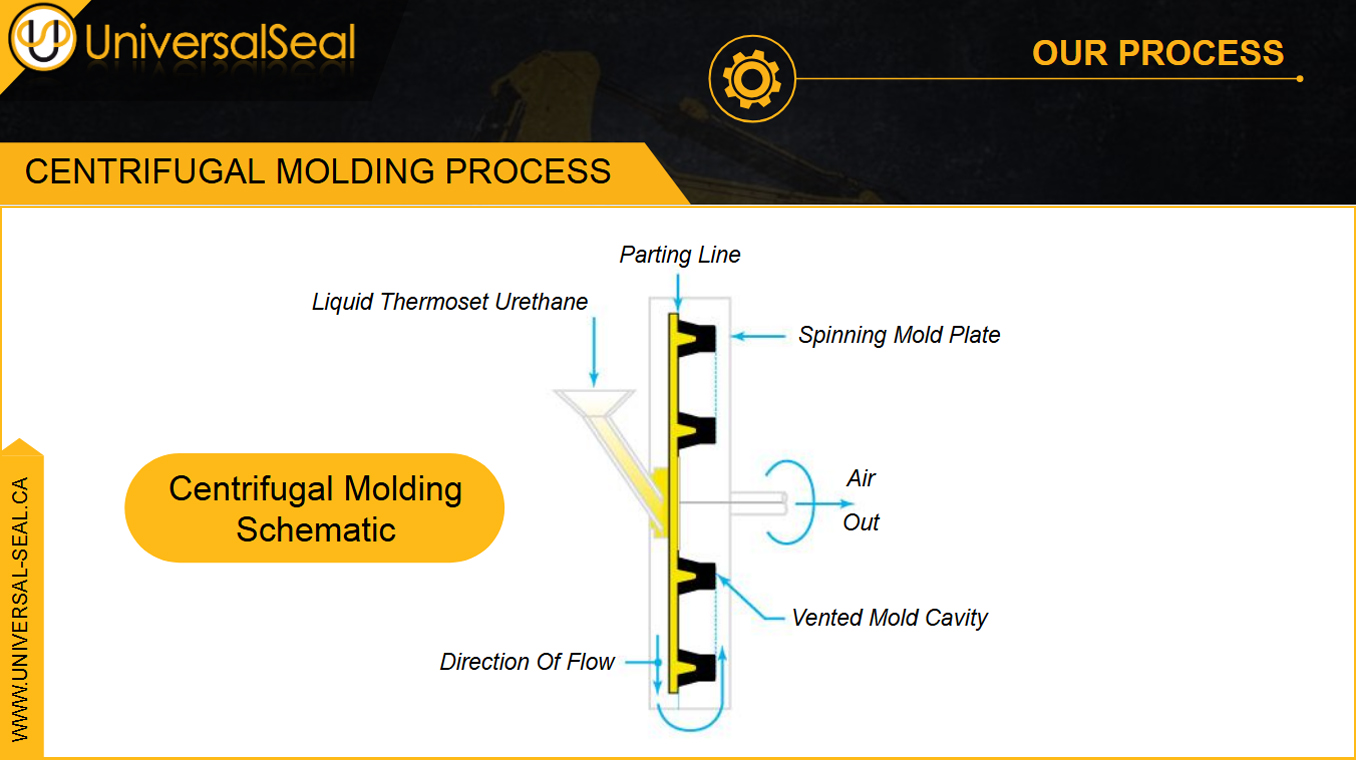

Additionally, at Universal Seal, we use centrifugal spinning of thermoset polyurethane, which enhances the material's properties.

Centrifugally spun thermoset polyurethane offers several advantages, making it a preferred material for various applications:

-

Enhanced Durability: The centrifugal process creates a denser and more uniform material, resulting in improved wear resistance and longevity.

-

Superior Strength: The spinning process aligns the polymer chains, enhancing the material's tensile and compressive strength.

-

Consistent Quality: Centrifugal spinning ensures a consistent and homogeneous product, reducing variability and defects.

-

Customization: The process allows for precise control over the material's properties, such as hardness and elasticity, to meet specific application requirements.

-

Reduced Porosity: The high-speed spinning reduces air entrapment, resulting in a less porous and more robust material.